Modules at a glance

✓ Backed by a multi national giant

✓ Reliable SaaS infrastructure with 24/7 availability

✓ Every customer gets a customized product

✓ Reduced cost

✓ Faster time to market with change requests

Full List of Modules

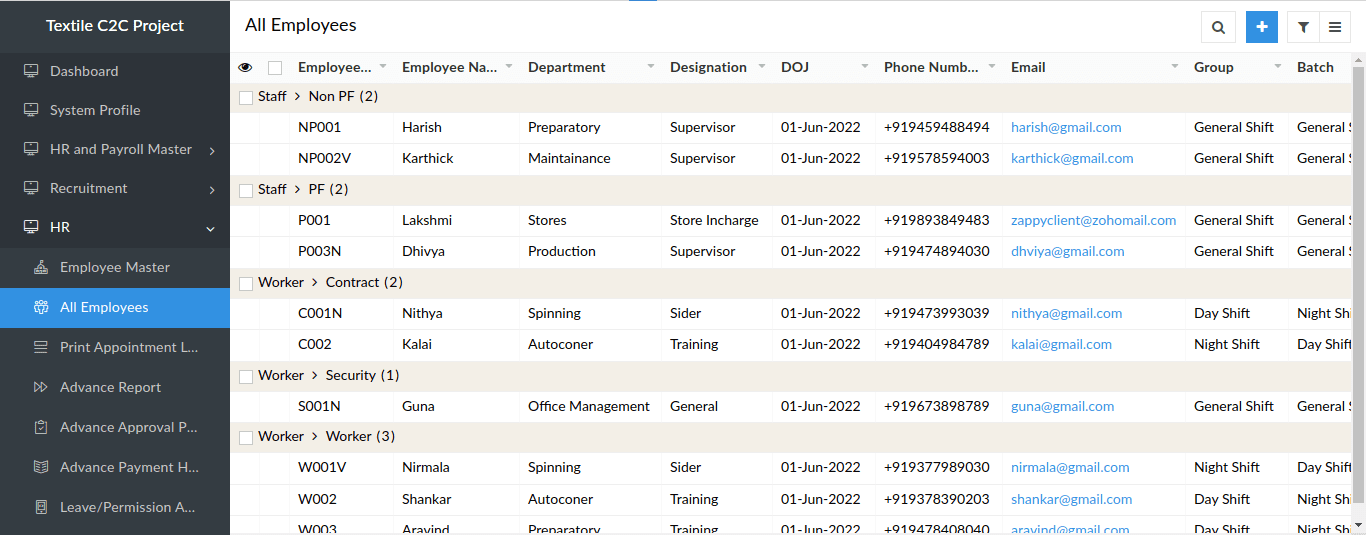

HR & Payroll

Employees (Staff/worker) are recruited and categorized into different subgroups. Their bio data, Payroll , ESI, PF and daily working shift against department is captured. Allowance and advances are also factored and a payroll is run.

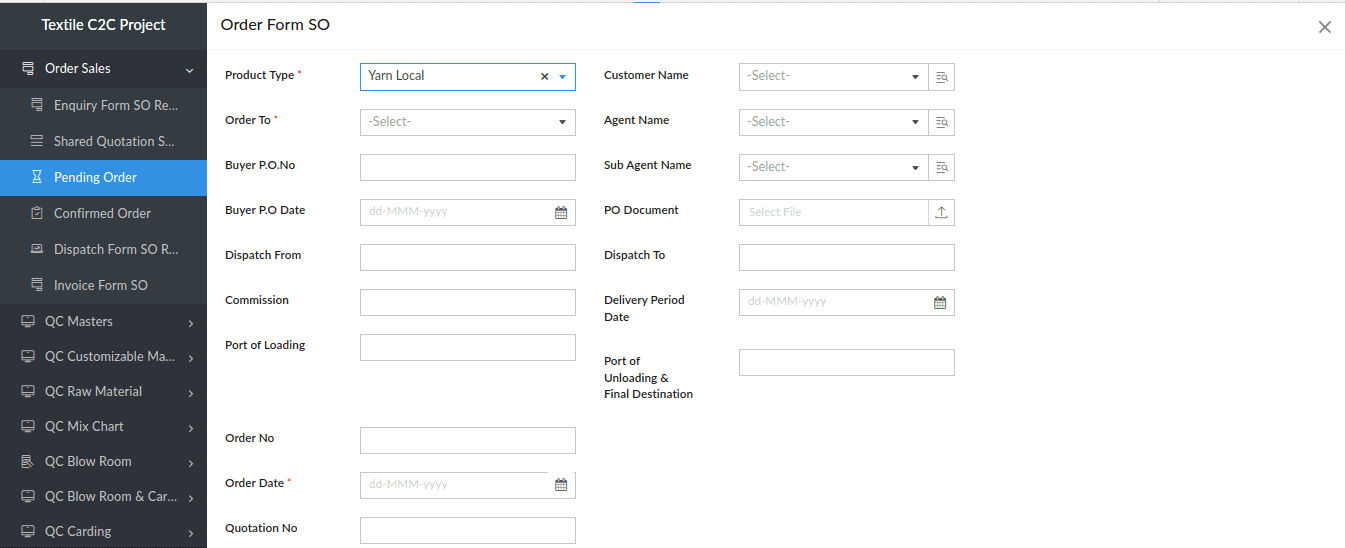

Order Sales & Marketing

Purchase order

Office Management

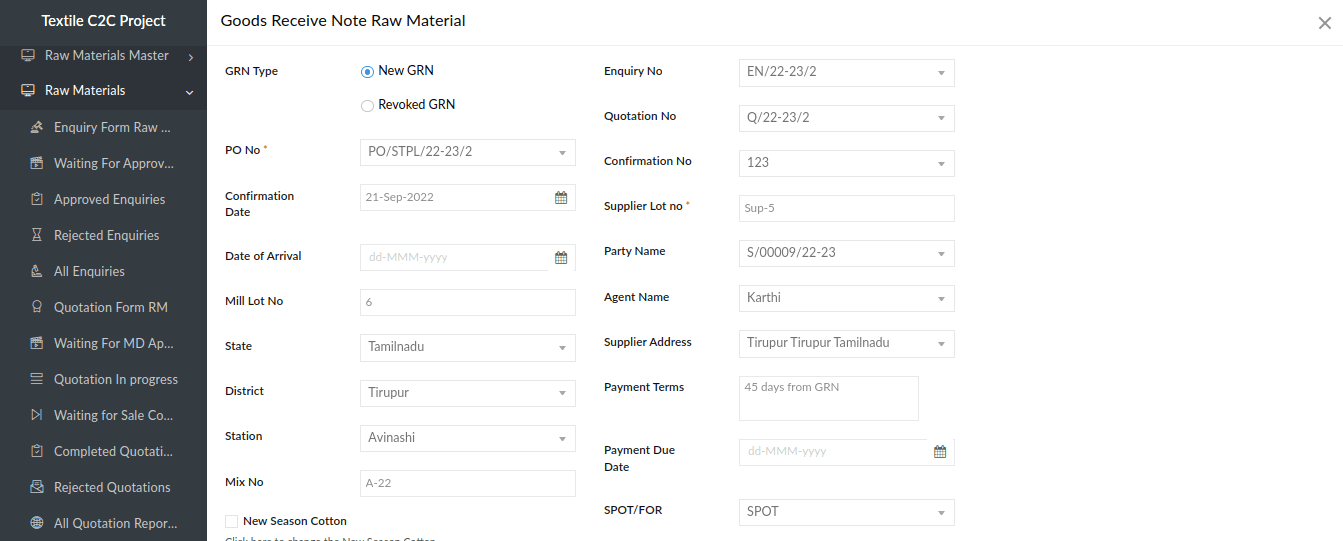

Raw Material Purchase

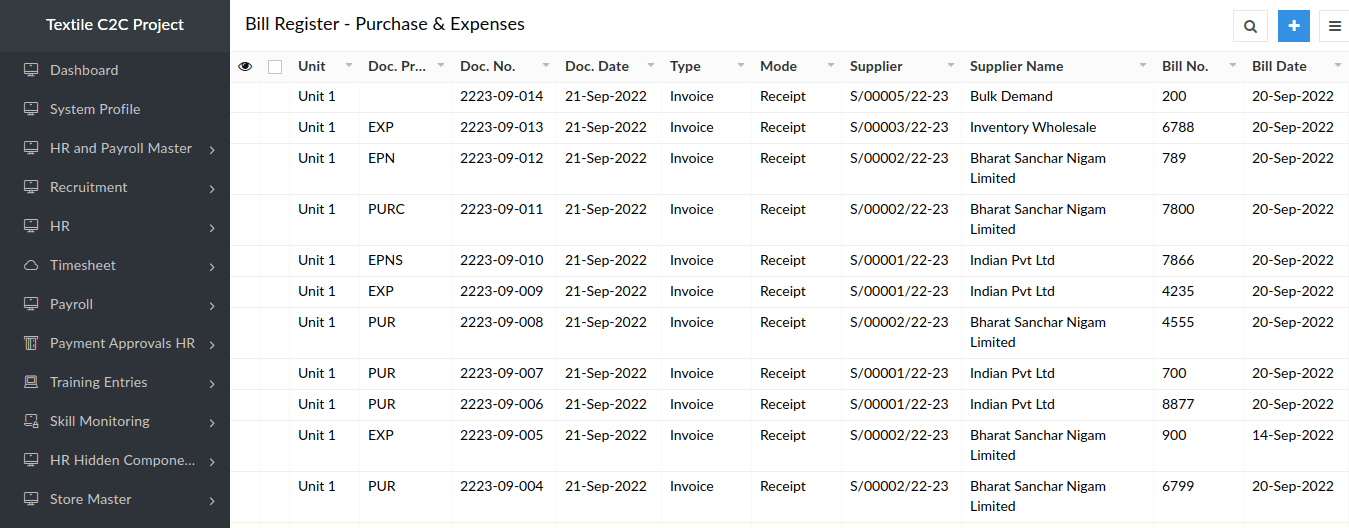

Finance & Accounts

Hostel & Canteen Management

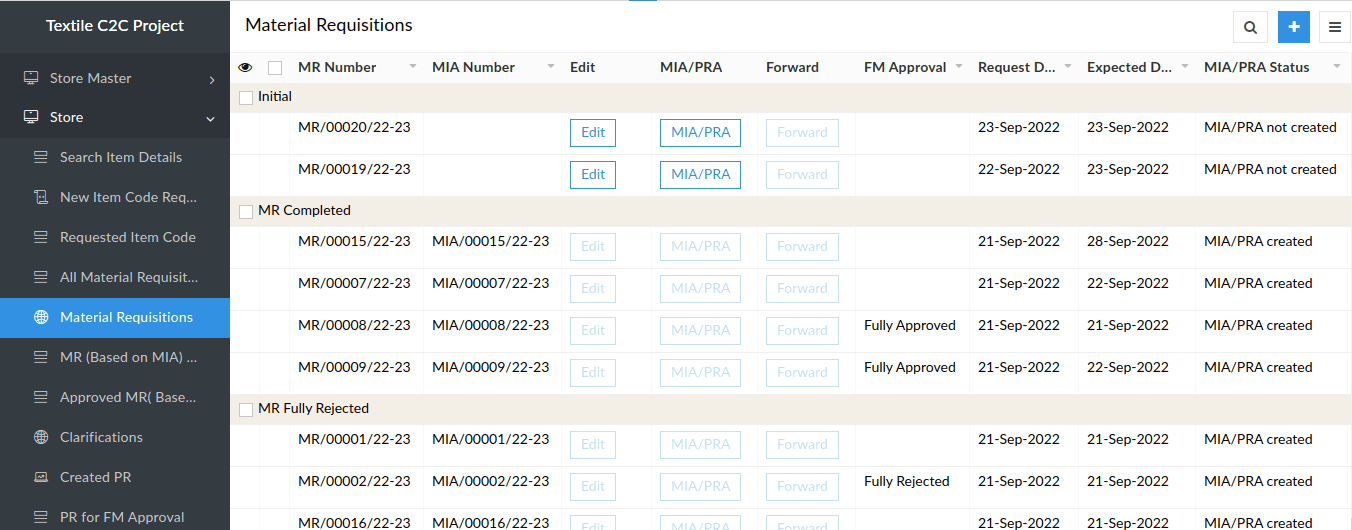

Stores & Inventory

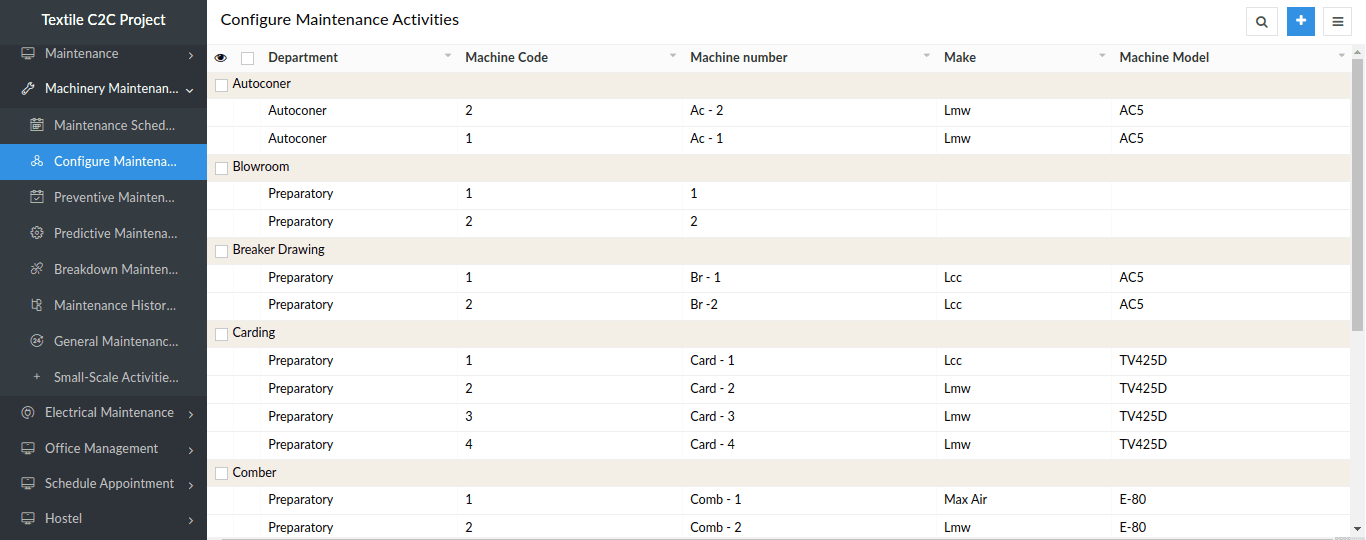

Maintenance

Power Management

HR & Payroll

Employees (Staff/worker) are recruited and categorized into different subgroups. Their bio data, Payroll , ESI, PF and daily working shift against department is captured. Allowance and advances are also factored and a payroll is run.

contact@aardhraa.com

contact@aardhraa.com